After the first trial production of glass packaging from the new furnace was launched on May 7, 2024, at the Serbian Glass Factory (SFS) in Paraćin, domestic Serbian customers have already received their first ordered products in recent days. The optimal production capacity of the furnace is 270 tons per day, and currently, approximately 350 pallets are being filled daily on three production lines in the company. Deliveries have begun, and this is important from the perspective of gradually establishing self-sufficiency, as the Serbian market almost entirely depends on the import of glass and glass packaging. In the coming months, production capacities will further increase due to automation.

After the international glass group Vaider Group took over SFS Paraćin at the end of 2022, it was first necessary to completely halt production due to the obsolescence of the old furnaces, followed by a year and a half of renovation work and the implementation of strategic investments worth 50 million euros for the modernization of production, supported by the Government of the Republic of Serbia. Upon the successful completion of the first investment cycle at the beginning of May this year, the first trial production of glass packaging from the new furnace successfully commenced at SFS Paraćin: “We have introduced new technologies, which our employees quickly adopted, which was not taken for granted, as this involves fundamentally more advanced technology and processes than those that existed at SFS Paraćin for decades,” said the General Director of SFS Paraćin and the Vaider Group, M.Sc. Peter Čas.

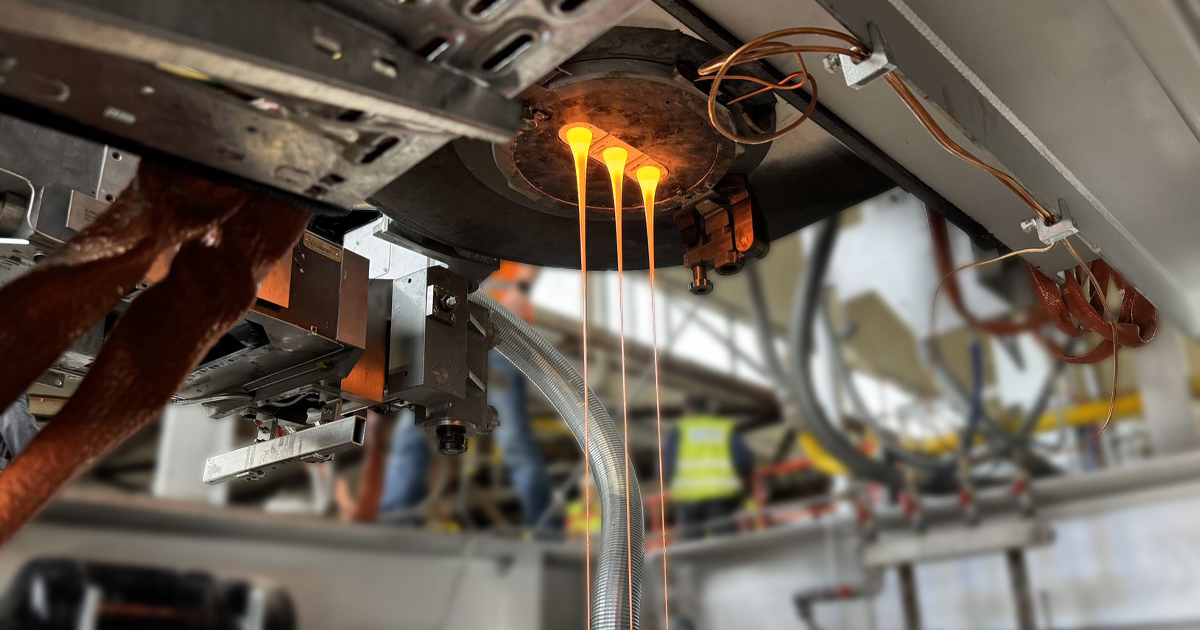

The AIS production machines, which turn molten glass into bottles, are the most advanced machines of their kind in the world – such developed devices have not yet been put into operation anywhere else – and they enable the production of over 300 bottles per minute at SFS Paraćin. They can produce a very wide range of glass packaging – from small bottles of just 10 ml to large jars and bottles of 2.5 liters and more. At the SFS Paraćin plant, they can recycle 200 tons of glass daily, with most of the raw materials coming from Serbia. “Each shift has about 120 employees, and 13 trucks – approximately 350 pallets of products – are shipped daily, with each pallet weighing an average of 700 kilograms. We see a lot of additional development potential, as we want to establish SFS Paraćin within the Vaider Group as a key manufacturer of glass packaging in Serbia and Southeastern Europe, thus not only reviving the Serbian glass industry but making it an export champion,” emphasized M.Sc. Čas.

When taking over SFS Paraćin, in addition to extensive investments and new jobs, Vaider Group committed to developing the local environment, so M.Sc. Čas further emphasizes, “that it is explicitly clear today that we keep and fulfill our promises. I would like to highlight that we are extremely grateful for the significant support of the investment from the Serbian government and the Development Agency of Serbia.”

Vaider Group’s goal is to become one of the leading European groups in the field of high-quality glass packaging and to provide clients with top products, services, and support, which is why it remains committed to realizing the announced investments in both the employees at SFS Paraćin and the development of production and other processes, thereby further contributing to the revival of the glass industry both in Paraćin and throughout Serbia.